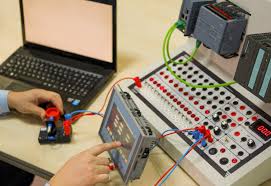

A manufacturing line runs smoothly only when humans and machines speak a shared language. In modern plants, that language is built on automation systems controlled by Programmable Logic Controllers. Understanding what is PLC programming allows plant operators to do more than press buttons—they grasp how every sensor, relay, and output signal contributes to production flow.

Operators Gain Stronger Control Through Process Awareness

Plant operators equipped with PLC programming knowledge manage processes with greater confidence. They can visualize how control logic sequences direct pumps, conveyors, and valves throughout the facility. This awareness allows them to make smarter adjustments during shifts, balancing speed, safety, and consistency.

Instead of relying solely on pre-set controls, an operator who understands what is PLC programming reads ladder diagrams, sees relationships between input and output, and notices when something deviates from expected behavior. This deeper control transforms the operator from a reactive worker to a proactive process specialist capable of improving system stability.

Production Flow Understood Better Through PLC Familiarity

Automation systems coordinate hundreds of actions every minute. Operators who know how a custom PLC works recognize why each timing interval, motor start, or pressure limit matters. This insight minimizes production interruptions and keeps lines balanced from one stage to the next.

With guidance from control system integrators, staff members trained in PLC programming can trace patterns across multiple systems, such as how a motor delay on one conveyor affects downstream packaging. That understanding improves workflow decisions and helps reduce inefficiencies that often go unnoticed by untrained personnel.

Equipment Responses Predicted Accurately with Programming Insight

Machines follow logic precisely as written in their PLC code. An operator familiar with Rockwell Allen Bradley PLC design can predict how equipment will respond before pressing a control key or starting a sequence. Anticipating those actions helps avoid sudden mechanical stress or energy waste.

This predictive skill becomes especially valuable during startup or shutdown cycles. Knowing the sequence order, delay timers, and interlocks reduces wear and prevents unsafe conditions. With practical knowledge of PLC programming, operators can plan maintenance around system responses rather than reacting to unexpected shutdowns.

Routine Troubleshooting Simplified by System Knowledge

Downtime costs facilities both time and revenue. Operators who understand what is PLC programming often resolve basic faults before calling a technician. By checking logic indicators or reading diagnostic screens, they identify whether a problem stems from a sensor failure, relay issue, or code-related delay.

Even minor familiarity with the program’s structure helps isolate recurring problems faster. In facilities supported by a PLC programming company, operators trained on their system can communicate clearly with engineers, speeding up troubleshooting and preventing repetitive breakdowns caused by small overlooked triggers.

Safety Procedures Strengthened Through Logic Understanding

Safety interlocks and emergency stops are built into PLC logic for a reason. Operators who comprehend how these layers of control interact with sensors and actuators maintain safer work environments. They know which signals trigger automatic shutdowns and can verify whether those safeguards remain active during maintenance or system testing.

Understanding how a custom PLC responds to abnormal conditions allows operators to detect early warning signs—such as misaligned sensors or unstable voltage—that could compromise safety systems. This knowledge ensures compliance with operational standards while keeping personnel and equipment secure.

Coordination Between Teams Improved by Shared Technical Language

Production, maintenance, and automation teams often rely on different technical vocabularies. Operators who understand PLC programming bridge that gap, using shared terms that describe system behavior accurately. This alignment improves collaboration during repairs, upgrades, and process evaluations.

In plants using Rockwell Allen Bradley PLC systems, coordinated communication prevents misinterpretation of fault codes or data tags. An operator’s ability to articulate how a signal chain functions saves time and fosters a more unified approach between departments, leading to smoother operation and faster recovery after maintenance tasks.

Minor Faults Resolved Faster with Informed Observation

Not every problem requires a full shutdown or engineering intervention. Operators trained in control logic can spot irregular sensor readings or output mismatches before they escalate into system errors. Their understanding of PLC structure makes pattern recognition more intuitive.

Small malfunctions, such as inconsistent temperature readings or motor overload warnings, often signal deeper logic conflicts. Knowledge of what is PLC programming allows operators to interpret alarms correctly and provide accurate feedback to control system integrators, reducing downtime and unnecessary part replacements.

Efficiency Maintained When Operators Recognize Logic Sequences

Efficiency depends on rhythm—every part of a production line must respond in perfect order. Operators familiar with PLC programming identify whether a delay or skipped cycle comes from a coding issue, mechanical lag, or network signal. Their recognition of logic sequences ensures that processes continue to meet timing benchmarks.

A plant operating under a custom PLC design benefits from personnel who understand these sequences intuitively. Instead of waiting for engineers to review every minor fault, trained operators maintain the process flow and uphold system performance. This consistent awareness helps keep productivity high while maintaining quality standards that support long-term plant success.